G. Boley C60 Bench Vise - Restored

This weeks projects included a few discarded vises. Among them a G. Boley C60 bench vise. A vise made specifically for and used by Watch and Clock makers and repair people and Jewelers.

The Boley C60's over all length is 7.5 inches and about 4 inches tall. It has a jaw width of 60mm. A DIN of 5115. It's a cute little vise that is very well made from what I can see. Of course, it didn't come into my hands looking quite so fancy, the opposite in fact. Someone had painted it at one time just to dress it up a bit from what it looked like, which probably saved it from being worse than it was. It really wasn't in bad shape.

I chose to finish it in a Candy Blue, with solid white lettering with plenty of high polish to make it pop. The finish is oil, gas and temperature resistant up to 500°F and I really felt that would be a good choice considering it's a vise that'll probably see some heat and oil, etc, etc.

Of course it had to be completely taken apart, stripped of paint, wire wheeled, etc. Seen below it's almost ready for paint.

Sorry, no pics of it taped up or the primer coats or any other coats before final finish. I'll tell you it wasn't quite as easy to tape up as you'd think it might be. It actually took me about 3 hours to mask it off. I went with 3M Fine line tape for this project.

I did all the polishing prior to painting. I used an acid etch primer first, (3 coats). Then white primer 3 coats, then silver undercoat 3 coats, then 4 coats of Candy Blue.

Let that all cure for over a week, then I did the lettering. Which I discovered a very cool way to achieve the lettering. I'll explain.

Normally you'd think to use a small brush and then wipe off excess right? Yeah, so did I at first. And one side, that's how I did it. To start with.

For this lettering you only need a small amount of paint, rather than pour paint or reducer or whatever you're using for your mix from the cans, I use those little disposable eye droppers. Pipettes is another name for them.

That's what I used to paint the letters. You just draw up a tiny bit of your paint mix into the pipette, hold it by the shaft so you can control the flow, and trace the letters. For the lettering on this vise it worked beautifully. Adding just the right amount of paint when needed, very little excess over the edges to clean up.

A note if you're going to try that method. You don't fill the letter up, you literally paint with the dropper. And you can shape the dropper end to fit into the groove you need. If the tip is too big, just squeeze it and make it oblong.

Hope that helps you if you run into recessed lettering you need to paint.

Here's some more pics of the finished G. Boley C60 vise:

I think you'll agree it came out nice. I didn't remove every imperfection before high polishing the steel given the history of this vise. I know the person that owned it prior built his life and long standing business from watch repair and jewelery. He long since retired, the business long gone and forgotten about before he finally passed. So I wanted to leave some of the working marks made in the vise as a sort of tribute to it's past owner, and/or owners prior to him.

One mod I did was to add handle bumpers. They prevent the clang you normally hear as the handle slides and the end hits the center.

Taking note of other vintage vises and what they used to lubricate them, I used a mid viscosity oil on the handle spindle and threaded areas.

I also waxed the rails with parafin and waxed the whole vise including bare metal with carnauba wax mix. A mix I've used on vessel stainless steel. If it works to protect metal on yachts, it should work fine on a vise.

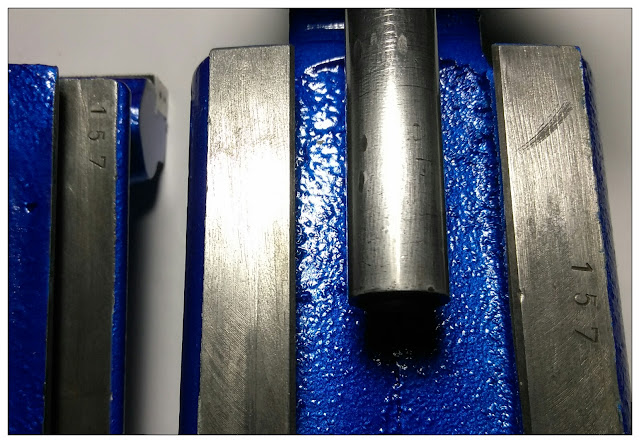

I don't know exactly how old this vise is. It does have a number 157 stamped into both the static and dynamic jaw guides.

I don't know if that's a date of production code or... the number of the vise as made.

Trying to find out and researching online I found very little... I don't find the answer to the question, but of what little I did find out about the company G. Boley was very interesting. Even more so after the founders death. Yes, G. Boley was a person. His name is Gustav Adolf Boley.

Rather than miss quote by using my own words, let me just quote some things.

From the German Wiki:

"Gustav Boley graduated in watchmaking in Stuttgart and then worked in Ulm , St. Gallenand La Chaux -de -Fonds , where he opened an action for watch accessories. In 1870 he returned to Germany; Two years later he bought a house in Esslingen and established the company G. Boley as the first watchmaking tool factory in Germany. Also precision machine tools and vices were produced there. Boley also exported its products abroad."

End quote.

G. Boley created lathes for watch and clock making as well as the vises and other watch and clock making tools. Medium size lathes and more and all G. Boley products are said and known to be precision high end tools.

G. Boley gets married, has a couple kids, the company takes off. It gets big. He dies in 1891.

His wife continued to run the flourishing company when in 1902 she brings in two partners. Their eldest son Willi and Josef Leinen.

You might recognize that last name if you're a Watchmaker, repair person or jeweler. That's right Leinen is the same name on currently made vises of a different design.

Now here's were it gets interesting...

Leinen was brought in as a partner in 1902, but quit only 2 years later 1904 to start his own company making vises. Which he called "Leinen".

He then wanted to start making clock and watchmakers lathes in direct competition with G. Boley who was already a well established company and name.

There was some obvious bad blood or something going on as G. Boley then copied his vise design adding it to their own.

Leinen goes out and finds some woman with the last name "Boley" and offers her a partnership and names the company "Boley and Leinen". Which is still in business today. And like today as it did then, it caused much confusion. As the two companies, G. Boley and Boley and Leinen have nothing to do with each other. It was simply a marketing strategy by Leinen.

A fact I wasn't aware of prior to emailing Boley and Leinen about this vise hoping they could date it for me. They never responded so...

I found this picture of the G. Boley and Company Facility online.

|

| G. Boley and Company 1924 |

|

| The end... Or is it? |

More from the German Wiki and I quote:

"In 1905 Paul Pfleiderer and 1912 Boley's second son Hans Gustav joined as partners. The descendants of Willi and Hans Gustav Boley as well as Pfleiderer continued the company for the next generations. In 1976, CNC lathes were sold for the first time . In 1985, computer-controlled machine tools already accounted for three-quarters of sales. The company became the property of the Citizen Group of Japan in 1992."

End quote.

So the original G. Boley was acquired by the Citizens Group who have been around just as long so I've read. The G. Boley division currently continues to design and produce CNC machines as of this writing.

I also read somewhere in a forum that production stopped sometime in the 60's or 70's of vises and other things as the G. Boley company focused more on CNC machines. Whether that's fact or just rumor I'm unsure.

And there you have it. That's all I could find out about this vise and the G. Boley company.

If you know how to date these vises and/or what the number 157 stamp stands for. Chime in in the comments.

If you have a G. Boley C60 vise, what numbers are stamped on yours? Please post in the comments.

I hope you enjoyed the read and seeing the outcome of this old vise. I'm pretty happy with it. Now to make a nice box for it.

Till next, stay creative, be happy.

Cheers....

So the original G. Boley was acquired by the Citizens Group who have been around just as long so I've read. The G. Boley division currently continues to design and produce CNC machines as of this writing.

I also read somewhere in a forum that production stopped sometime in the 60's or 70's of vises and other things as the G. Boley company focused more on CNC machines. Whether that's fact or just rumor I'm unsure.

And there you have it. That's all I could find out about this vise and the G. Boley company.

If you know how to date these vises and/or what the number 157 stamp stands for. Chime in in the comments.

If you have a G. Boley C60 vise, what numbers are stamped on yours? Please post in the comments.

I hope you enjoyed the read and seeing the outcome of this old vise. I'm pretty happy with it. Now to make a nice box for it.

Till next, stay creative, be happy.

Cheers....

Hi,

ReplyDeleteThe factory worker who made this vise, did manually adjust dovetail's female and male parts as a whole fitting process. He machined (handscraped ?) it until the fit went right, the way one does for a lathe's table or crosslide.

Thus the 157 male part would not have such a close fitting with another female vise number.

157 male is paired with 157 female.

You may encounter this numbering for many old precise tools, even on old clocks (before 1900) or cylinder watches.

Thank you very much for the added information Anonymous.

DeleteThat would explain the "B" also stamped on static jaw guide rail.

Cheers...